According to the U.S. Coast Guard, flooding and resultant capsizings are responsible for about 50% of fishing vessel casualties. Maintaining a watertight envelope, including watertight doors, is key to keeping the ocean out of your vessel.

But what is a watertight door?

A watertight door, according to the Coast Guard, is “a space constructed to withstand a static head of water without any leakage.” Whereas a weather-tight door is “a door that water will not penetrate into the unit in any sea condition.”

In other words, a watertight door should not leak even when there is a head of water on the opposite side of the door, as opposed to a weather-tight door that is just designed to keep the weather and normal seas from leaking through the door.

To give an idea of the water pressure a watertight door must withstand, an eight-foot door in a flooded space will have about four pounds of pressure per square inch (psi) on the door. A 30-inch by 50-inch door has 1,500 square inches of surface face on it. 1,500 square inches at 4psi equals 6,000 pounds of pressure against that door!

If the door is not properly maintained, the interior space will progressively flood, but unfortunately, watertight doors often do not get as much love as the rest of the vessel receives. The following are inspection points you can take to ensure that your watertight door will keep the ocean on the correct side of the door:

Steps for a chalk test to ensure that the gasket is in touch with the knife edge:

- Clean the knife edge on the door and the gasket on the doorway.

- Rub chalk on the knife edge and close and dog the door.

- While closed, check for loose dogs, adjust and repeat. The gasket should compress about an eighth of an inch.

- Open door and the chalk line should be continuous and in the center three-fifths of the exposed gasket.

- When opening the door, it should have no more than 3/16″ of play in the hinges. If so, check hinge pins, washers and holes for wear.

- If hinge pin washers are less than 1/32″ in thickness, damaged or worn, they should be replaced.

Gasket care:

- Replace the door gasket when it becomes hardened, cracked, permanently grooved or when pieces are missing or not meeting. Do not splice a section in; replace the entire gasket.

- Keep gaskets clean and free from paint and rust.

- When replacing the gasket, the gasket joint should be on the top of the door. Cut a 45 degree angle where the ends meets so they overlap about one inch.

- Lubricate gasket with silicone oil.

Keeping dogging devices greased and properly adjusted:

- Are straight bushings firmly seated against dog back and free of rust, paint and dirt? If bushing is stuck to spindle sleeves, lubricate.

- Are flanged bushings firmly seated against the end of the dog sleeve held by the set screw? Look carefully; the set screw may have been painted over.

- For dogs with self-lubricating brushings—ensure a CRES (Corrosion Resistant Steel) washer is between the dog lever and face flanged bushing.

- Give each dog spindle a shake up and down and side to side. If the spindle moves, you may need to replace spindle sleeve or the entire closure.

- Check that both the jam and self-locking nuts are tight on each dog.

- Remove any paint, rust and dirt.

Handle inspection for quick action doors:

- Work the handle through its full cycle for signs of binding. Check handle nuts and dog adjustments.

- If the door must be raised to close, hinge pins are worn, or the hinge pad may be enlarged.

- If door won’t open from the inside, the handle on opposite side has slipped its spindle or fallen.

- Inside and outside handles should line up for free movement.

Handle inspection: individual dogged doors:

Work the handle through its full cycle. If there’s no free movement, disassemble and lubricate.

Bushing on dog mechanism will either be string and stick packing or self-lubricating.

Hatch inspection:

- Check knife edge and gasket for distortion. Perform a chalk test.

- To check distortion clean edge/gasket of dirt, rust, paint and nicks with an aluminum oxide abrasive and wipe with clean rag. Use a 30 to 35-inch straight edge against knife edge. There should be no deviation more than one 16th of an inch. Edge height should be 1-7/16″ with no deviation more than an eighth of an inch.

- Inspect dog bolt nuts for wear and that the dog bolt wrench grips it properly.

- Check the collar of the securing nut when the hatch is opened to make sure it’s not missing from the top of dog bolt.

- Lubricate dog bolts with silicon.

- Test the brace by opening hatch and ensuring the brace will hold hatch cover open and the toggle bolt is the correct size to secure the free end of the brace to the coaming.

- Check hinges for missing cotter pins and washers.

- Wrench in place? Individual dogged hatches have an engineer’s wrench in place. Flush handles have T-wrench inside.

- Make sure the open detention device on all doors and hatches are intact and workable.

So there you have it. A well maintained watertight door. However, if your door is left open when it should have been closed, all of the above is for naught.

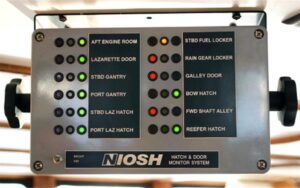

For this, there are door and hatch monitoring systems available that can be located in the wheelhouse so that the watch can see what doors or hatches are open (red), closed but not secure (yellow) or secured close (green).

NIOSH has designed such a monitoring system for fishing vessels which is produced by a private company and other models are also available on the market to help the vessel’s watertight envelope remain watertight.

The Alaska Marine Safety Education Association (AMSEA) has a mission is to reduce injury and death in the marine and freshwater environment through education and training provided by a network of marine safety instructors. The Sitka, Alaska-based organization has been offering marine safety training to commercial fishermen and thousands of other mariners since 1985.

More information on marine safety topics can be found at www.amsea.org