“It’s a monster.” Cummins Inc. and Elliott Bay Design Group team up for a highliner-oriented Bristol Bay boat.

Imagine you’re aboard grandpa’s fiberglass gillnetter on Bristol Bay for yet another (hopefully) gangbusters salmon season. Another gillnetter zooms past at 20 knots propelled by triple UltraJet 340HTs with a full load of fish in the hold.

“I hear that thing can carry 20,000 pounds!” Grandpa says. No way, Gramps is spreading bar-side gossip again, you think.

Such a scene is closer to reality than one might believe. A partnership between Cummins Inc’s Mike Fourtner—who in addition to being commercial marine sales manager of Cummins is a working Bristol Bay fisherman—and Seattle-based Elliott Bay Design Group (EBDG) have led to what is at the time of this writing officially dubbed the Bristol Bay Gillnetter.

According to a Cummins/EBDG news release: “EBDG and Cummins partnered to design an ultra-shallow, triple jet gillnetter capable of making 20 knots with 20,000-pound fish capacity. The vessel is equipped with the latest technology, safety features and propulsion.”

A natural first question about any new boat design is: why does this boat exist?

“The boat was largely a response to the large numbers at Bristol Bay,” EBDG Project Manager David Turner said when asked about the market demand for such a boat. “We just started working up the design with Mike (Fourtner), (with) his experiences in Bristol Bay, and this is where we ended up.”

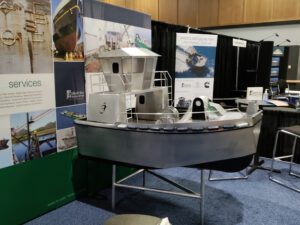

Also in the partnership orbit is Tacoma, Wash.-based aluminum boatbuilder Silverback Marine that co-exhibited with EBDG in New Orleans at the International Workboat Show with an impressive model of the gillnetter. Earlier this year, Silverback Marine founder Ian Gracey had the 6.5-foot aluminum model displayed prominently in his office.

“It’s a radical boat obviously,” Gracey said. “As you probably notice, at every boat show there are these cute little models in little glass cages, but it’s not very exciting. We asked Elliott Bay, as we’d be potential builder for this boat, ‘hey, could we partner up? We’ll get some marketing exposure, we’ll build this model for you to show it at the show and share booth space.’ We built it and turned a lot of heads at the show.”

The Build—20 Knots, 20,000 Pounds

The guiding design philosophy is all about starting with ambitious build targets and trying to reach them.

“We started out with the parameters we wanted. We wanted it to be able to carry 20,000 pounds and hit 20 knots (loaded),” Turner said. “Shallow draft was a consideration and obviously it has the 32-foot length limit. We started scaling outward to see what kind of beam it would take to hit those numbers, so that’s how we ended up with 20 feet.”

The result is a bit like strapping three jets to an aluminum bathtub.

“The numbers on it are kind of ridiculous, doing 20 knots with 20,000 pounds of fish on it,” continued Turner. “That’s why it has the outrageous amount of beam. It’s not a pleasure boat.”

“It’s a monster,” Gracey admitted. “The Bristol Bay fishery is unique because you got guys who got a 30-day window to get their stuff in. The concept behind such a large boat is to move as much fish as you can as quick as you can.”

Turner explained that the engine and jet package—three Cummins QSB6.7 550-horsepower engines with three UltraJet 340HTs—was one of the earliest design decisions of the build due to the desirable power-to-weight ratio.

Other ancillary benefits of jet propulsion for Bristol Bay working life is shallow water operation, maneuverability and generally less trouble with net entanglement.

“The way we see the boat operating typically is that just the two outboard engines would be running,” Turner explained. “That’s enough to get them out to the fishing grounds. When they are maneuvering out there with two engines that would work very well. The centerline engine would only be used for getting back to the dock with a full load. (It) probably wouldn’t have a bucket on it, wouldn’t be steerable, it would give it that extra boost of power.”

Turner stated that the build is an evolution that relies upon the successes and next level goals of current Bristol Bay boats, not a revolutionary change that reinvented the game. The result should be a working boat that’s familiar to highliner leaderboard-driven owner-operators who want to perform even better.

“Again, it’s a numbers-driven exercise. We have these certain targets, design parameters, and this is one way you can get to them,” Turner said. “And the beam is really restrictive, so the hull form you get doesn’t have much for deadrise, (it’s) definitely not a hull built for comfort.”

Current Status

When will we see the first Bristol Bay gillnetter zipping past at crazy fast, top speeds? Whenever the first interested partners step up. Regarding the cost, Gracey noted that a new Bristol Bay boat will typically sell for around $1.2 million.

“It’s a lot of money for a boat you use one month out of the year,” Gracey said. “However, it’s exciting to move that much fish that fast.”

To combat sticker shock, EBDG proposes offering a range of packages starting at the basic aluminum structure and engine package installation—or even more basic at the aluminum cutting level—as an entry point. Deluxe turnkey packages would be offered at the higher end.

“The way we see things coming together, we’d offer a structural package and leave a lot of the outfitting to the individual,” Turner said. “Some of these fishermen like to do their own outfitting of the boats, but they definitely have their own ideas of what the outfitting should be.”

“We understand that aluminum is expensive and it’s hard for people to fork over that kind of money, so we recently embraced the idea of just building just the hull for somebody,” Gracey added. Silverback Marine would be a potential builder involved in these differing package entry points.

What a Beast

At the end of the day, what is the pitch for this build? The numbers.

“I really think the hard pitch is in the numbers,” Turner said. “Twenty knots with 20,000 pounds aboard. Be first back (to) the dock.”

“Elliott Bay is just a really solid company with excellent customer service, really the kind of people we want to work with,” Gracey said.

What does he think will be the public’s first reactions to seeing a such a vessel flying past?

“People will just be like, man, that’s a beast!”

Norris Comer is a Seattle-based writer and author. His debut memoir, Salmon in the Seine: Alaskan Memories of Life, Death, & Everything In-Between is now available wherever books are sold. You can find him on Substack, Instagram and at norriscomer.com. He can be reached via email at norriscomer@substack.com.